300 WSM & 7 SAUM rate of increased MV??

Moderator: Mod

-

DenisA

- Posts: 1526

- Joined: Wed Nov 09, 2011 7:00 pm

- Location: Sunshine Coast, QLD

300 WSM & 7 SAUM rate of increased MV??

I have a question for the 7 SAUMERS and 300 WSMERS on here. It's common knowledge that .284W's speed up with a few hundred rounds. I'm guessing most cartridges do at different rates. I've experienced this in 3 .284W barrels and its slow enough to be easily manageable.

With my .300wsm & 185 jugs, I had it tightly tuned by 84 rounds total. The MV was just under 2920fps at 67.1gn ar2213sc. At 200 rounds my 67.1gn had me up at 3000 fps, still very tight groups. Long story short, I have 300 rounds on it now and I've had to come down to 64.5gn ar2213sc to maintain 2920fps. I'm hoping this thing starts to settle soon.

The barrels cleanliness is well maintained..

Do the 7SAUMS speed up this quickly too?

Has anyone else playing with 300wsm's experienced the same?

Is this a string shooting magnum characteristic?

Thanks.

With my .300wsm & 185 jugs, I had it tightly tuned by 84 rounds total. The MV was just under 2920fps at 67.1gn ar2213sc. At 200 rounds my 67.1gn had me up at 3000 fps, still very tight groups. Long story short, I have 300 rounds on it now and I've had to come down to 64.5gn ar2213sc to maintain 2920fps. I'm hoping this thing starts to settle soon.

The barrels cleanliness is well maintained..

Do the 7SAUMS speed up this quickly too?

Has anyone else playing with 300wsm's experienced the same?

Is this a string shooting magnum characteristic?

Thanks.

-

RDavies

- Posts: 2323

- Joined: Sun Feb 12, 2006 7:23 pm

- Location: Singleton NSW

Re: 300 WSM & 7 SAUM rate of increased MV??

I would say every barrel is different.

I have had a dozen 284s and all picked up speed to varying degrees. I have heard of some picking up speed continually for quite a while, needing retuning for up to 3-400 rounds, while others had a quick slight velocity kick at 150 rounds.

I have had a total of 1x 300WSM (button rifled) and it has been speeding up from around shot 70 to shot 180, not sure when it will stop.

My first 7 SAUM (different brand, cut rifled) was the first barrel I have had which hasn't sped up (450 rounds s far). I have another 7 SAUM from the same barrel maker being tested, with another coming soon. I wouldn't have a clue if these will act the same as the first. I don't think it is calibre specific, but barrel specific.

I have had a dozen 284s and all picked up speed to varying degrees. I have heard of some picking up speed continually for quite a while, needing retuning for up to 3-400 rounds, while others had a quick slight velocity kick at 150 rounds.

I have had a total of 1x 300WSM (button rifled) and it has been speeding up from around shot 70 to shot 180, not sure when it will stop.

My first 7 SAUM (different brand, cut rifled) was the first barrel I have had which hasn't sped up (450 rounds s far). I have another 7 SAUM from the same barrel maker being tested, with another coming soon. I wouldn't have a clue if these will act the same as the first. I don't think it is calibre specific, but barrel specific.

-

williada

- Posts: 969

- Joined: Wed Jul 22, 2009 12:37 am

Re: 300 WSM & 7 SAUM rate of increased MV??

Denis you ask all the right questions. Last year I sent some info to Tony with regards to getting over the hump and maybe he has kept data on his 7 mm. My direct experience comes from 30 cal and using a bore micrometer as pictured to track the bore and lands for general wear together with a bore scope.

The thing about tuning, things are never constant, mechanically or environmentally. In terms of mechanical, I break the barrel life cycle into wear categories to get the most optimum value for my money. Like Peter, I cut long barrels down until they get progressively shorter as I cut out the worn sections.

We all know about breaking a new barrel in with 5-30 shots. The basic function here is to smooth the throat area which has been roughened in the bore when the chamber reamer cuts across it. Did you know the famous barrel maker Harry Pope who holds that tight 10 shot group pictured in the stick note on recoil chambered the barrel before it was rifled and fitted a bored plug into the chamber to accommodate the rifling cutter? That's how important he thought the throat was. He also used a scrape cutter rather than a hook cutter which gives a superior finish but is oh so time demanding to complete the job. Both are methods of cut rifling.

However, this is not seasoning a barrel to get across the hump as to speak when the barrel settles down. Getting across the hump occurs with a lot of barrels when the velocity increases to a point or hump, then begins to taper off as the bore wears. It may take about 150 rounds, sometimes much less and sometimes much more depending on the steel, its hardness and pore state.

The increase in speed is sometimes caused by the swelling of the metal micro structure and work hardening particularly in stainless barrels when combustion impurities first penetrate a relatively softer surface. This is likely to increase the pressure due due to metal swelling but in some cases, the barrel has not been lapped to a professional standard, is a bit rougher, and can offer resistance therefore increasing pressures and hence velocity. It was PO Ackley that favoured letting the bullet do the lapping. Krieger barrels utilize freezing cryogenically with nitrogen in their heat treatment. Experiments I have seen on bolts demonstrate that the closing of metal pores can be achieved to a point that the bolts resist salt and rust corrosion. So maybe there is something in Kreiger’s approach with regard to the micro structure that resists the penetration of combustion contaminants in the first instance.

The relevance for tuning is to determine those things that don’t count as much for the first 150 rounds. Firstly, you can prepare your cases by firing lower charges to protect the case primer pocket. You can conduct a primer test or maybe a powder test to see what the barrel likes relatively speaking. As you get closer to the 100 round mark, then you can determine a suitable charge weight with a bit more zip on previously fired cases and get a better idea of the velocity parameters.

As you approach 150 rounds the seating depth test will be meaningful as the throat is fully conditioned and the bore is reaching its optimum condition.

Your window of best shooting then may extend to 700-900 rounds as you are now past the hump. Top shooters may then nip the chamber and crown up for the next wear cycle which is roughly the 1500 round mark. At which time a final nip and or relegation to club shooting of the barrel takes place if sufficiently worn. You can be more precise with the proper investigative tools. Hope this helps. David.

The thing about tuning, things are never constant, mechanically or environmentally. In terms of mechanical, I break the barrel life cycle into wear categories to get the most optimum value for my money. Like Peter, I cut long barrels down until they get progressively shorter as I cut out the worn sections.

We all know about breaking a new barrel in with 5-30 shots. The basic function here is to smooth the throat area which has been roughened in the bore when the chamber reamer cuts across it. Did you know the famous barrel maker Harry Pope who holds that tight 10 shot group pictured in the stick note on recoil chambered the barrel before it was rifled and fitted a bored plug into the chamber to accommodate the rifling cutter? That's how important he thought the throat was. He also used a scrape cutter rather than a hook cutter which gives a superior finish but is oh so time demanding to complete the job. Both are methods of cut rifling.

However, this is not seasoning a barrel to get across the hump as to speak when the barrel settles down. Getting across the hump occurs with a lot of barrels when the velocity increases to a point or hump, then begins to taper off as the bore wears. It may take about 150 rounds, sometimes much less and sometimes much more depending on the steel, its hardness and pore state.

The increase in speed is sometimes caused by the swelling of the metal micro structure and work hardening particularly in stainless barrels when combustion impurities first penetrate a relatively softer surface. This is likely to increase the pressure due due to metal swelling but in some cases, the barrel has not been lapped to a professional standard, is a bit rougher, and can offer resistance therefore increasing pressures and hence velocity. It was PO Ackley that favoured letting the bullet do the lapping. Krieger barrels utilize freezing cryogenically with nitrogen in their heat treatment. Experiments I have seen on bolts demonstrate that the closing of metal pores can be achieved to a point that the bolts resist salt and rust corrosion. So maybe there is something in Kreiger’s approach with regard to the micro structure that resists the penetration of combustion contaminants in the first instance.

The relevance for tuning is to determine those things that don’t count as much for the first 150 rounds. Firstly, you can prepare your cases by firing lower charges to protect the case primer pocket. You can conduct a primer test or maybe a powder test to see what the barrel likes relatively speaking. As you get closer to the 100 round mark, then you can determine a suitable charge weight with a bit more zip on previously fired cases and get a better idea of the velocity parameters.

As you approach 150 rounds the seating depth test will be meaningful as the throat is fully conditioned and the bore is reaching its optimum condition.

Your window of best shooting then may extend to 700-900 rounds as you are now past the hump. Top shooters may then nip the chamber and crown up for the next wear cycle which is roughly the 1500 round mark. At which time a final nip and or relegation to club shooting of the barrel takes place if sufficiently worn. You can be more precise with the proper investigative tools. Hope this helps. David.

-

DenisA

- Posts: 1526

- Joined: Wed Nov 09, 2011 7:00 pm

- Location: Sunshine Coast, QLD

Re: 300 WSM & 7 SAUM rate of increased MV??

Thanks Rod and David for your info.

David, I don't know if I'm asking the right questions or not, but being a bit of a dopey bugger I have a lot of questions to ask.

That barrel micrometre is a flash tool. I've never seen one before. Would you only use it to measure the throat area? Was that done at each land and each groove? What are it's increments of measurement?

I remember a statement made by another experienced member a while ago. He said that the dirt and dust enters the muzzle naturally and can wear the muzzle end more aggressively, hence the advantage of taking a little more off on a re-crown. Have you seen this as measurable wear using your barrel micrometre?

Do you think there would be a significant difference in conditioning the bore to reach the hump if a nylon brush was used for cleaning rather than a bronze brush?

The reason that I ask is that for this barrel and my current .284W barrel, for the first time I have only used nylon brushes. Thought I'd see how Nylon V's Bronze affects barrel life and cleanliness.

David, I don't know if I'm asking the right questions or not, but being a bit of a dopey bugger I have a lot of questions to ask.

That barrel micrometre is a flash tool. I've never seen one before. Would you only use it to measure the throat area? Was that done at each land and each groove? What are it's increments of measurement?

I remember a statement made by another experienced member a while ago. He said that the dirt and dust enters the muzzle naturally and can wear the muzzle end more aggressively, hence the advantage of taking a little more off on a re-crown. Have you seen this as measurable wear using your barrel micrometre?

Do you think there would be a significant difference in conditioning the bore to reach the hump if a nylon brush was used for cleaning rather than a bronze brush?

The reason that I ask is that for this barrel and my current .284W barrel, for the first time I have only used nylon brushes. Thought I'd see how Nylon V's Bronze affects barrel life and cleanliness.

-

williada

- Posts: 969

- Joined: Wed Jul 22, 2009 12:37 am

Re: 300 WSM & 7 SAUM rate of increased MV??

Denis you are encouraging people to ask and learn from a number of people. Speaking for myself, I know the pleasure gained from giving someone the right tools to get the job done.

Harold Ryan only made a few of these tools about 37 years ago so you won’t see them on the market. I still have a couple, his first and a spare as I sold them on Harold’s behalf at times because he didn’t venture out much to prize meetings. You can dial anything in from .295” to .310” and read between lines for tenths of thou. In that range you can pick up bore or land measurements. It’s your choice. I always back that up across the bearings with a second micrometer. A tapered internal shaft pushes against ball bearings so it’s firm. Because the balls roll, you can gently move the tool fore and aft on a fixed setting to feel for variance but it is no substitute for a bumped up lead lap to feel for variance.

A few of us learned the hard way to use the tool, as too much pressure dialling in the size can indent the barrel with those fine ball bearings. Gentle, gentle, but effective because you can measure the entire length of the bore or groove. If you use bore gauges or the pilot off a reamer for measurements, they will not tell you what the groove is doing unless you make a star gauge. Simple stare gauges can be made from bore gauges by cutting wide, short longitudinal slots to allow the rifling to slip through so you can measure the groove.

The best indicator for the throat is of course keeping track of the seating depth.

I am a fan of a stiff bronze brush to remove the bigger problem of carbon - of course I re-check with a bore-scope after patching out again. A stroke forward for every shot fired after using solvent on several patches and jag so the brush does not pick up unnecessary gunk. You must clean your bronze brush in kerosene. It’s the gunk and dirt a brush carries that does the damage and particularly at the muzzle if you draw in back. That same gunk also attaches to a nylon brush but the nylon brush often fails to remove carbon. Carbon does not dissolve but its removal can be assisted by simple soap and water getting under it to assist lifting it off, not to mention boiling water. A bronze brush won’t mark the steel and it is more effective on carbon than nylon. If you keep a barrel clean from the beginning you stabilize its dimensions by letting the bullets do the lapping as Ackley once said.

Of course you can lap out the carbon. I attach some pictures on how, which I slipped Tony some time ago. Never use paste on a patch for this because contact is so bad you will wear things unevenly. This is a newer method found on Youtube which I adapted. Make sure the stem of the lap is pre-heated or the lead may freeze on pouring in small calibres. You can warm your barrel with a hair drier.

Some people think the muzzle wears from dust but the most likely culprit is the funnel shape created during manufacture by the lapping process when the grit laden lap is drawn back. The crown should always be measured and cut at the smallest internal diameter.

Yes, anything like dust can enter the muzzle but I cannot say it was measureable but it has a greater chance of scoring the bore. I once had a grain of sand inadvertently drop from a hovering scorer in rain from their umbrella into my action at Lang Lang and scrape a groove, on the right lug of a new action.

Harold Ryan only made a few of these tools about 37 years ago so you won’t see them on the market. I still have a couple, his first and a spare as I sold them on Harold’s behalf at times because he didn’t venture out much to prize meetings. You can dial anything in from .295” to .310” and read between lines for tenths of thou. In that range you can pick up bore or land measurements. It’s your choice. I always back that up across the bearings with a second micrometer. A tapered internal shaft pushes against ball bearings so it’s firm. Because the balls roll, you can gently move the tool fore and aft on a fixed setting to feel for variance but it is no substitute for a bumped up lead lap to feel for variance.

A few of us learned the hard way to use the tool, as too much pressure dialling in the size can indent the barrel with those fine ball bearings. Gentle, gentle, but effective because you can measure the entire length of the bore or groove. If you use bore gauges or the pilot off a reamer for measurements, they will not tell you what the groove is doing unless you make a star gauge. Simple stare gauges can be made from bore gauges by cutting wide, short longitudinal slots to allow the rifling to slip through so you can measure the groove.

The best indicator for the throat is of course keeping track of the seating depth.

I am a fan of a stiff bronze brush to remove the bigger problem of carbon - of course I re-check with a bore-scope after patching out again. A stroke forward for every shot fired after using solvent on several patches and jag so the brush does not pick up unnecessary gunk. You must clean your bronze brush in kerosene. It’s the gunk and dirt a brush carries that does the damage and particularly at the muzzle if you draw in back. That same gunk also attaches to a nylon brush but the nylon brush often fails to remove carbon. Carbon does not dissolve but its removal can be assisted by simple soap and water getting under it to assist lifting it off, not to mention boiling water. A bronze brush won’t mark the steel and it is more effective on carbon than nylon. If you keep a barrel clean from the beginning you stabilize its dimensions by letting the bullets do the lapping as Ackley once said.

Of course you can lap out the carbon. I attach some pictures on how, which I slipped Tony some time ago. Never use paste on a patch for this because contact is so bad you will wear things unevenly. This is a newer method found on Youtube which I adapted. Make sure the stem of the lap is pre-heated or the lead may freeze on pouring in small calibres. You can warm your barrel with a hair drier.

Some people think the muzzle wears from dust but the most likely culprit is the funnel shape created during manufacture by the lapping process when the grit laden lap is drawn back. The crown should always be measured and cut at the smallest internal diameter.

Yes, anything like dust can enter the muzzle but I cannot say it was measureable but it has a greater chance of scoring the bore. I once had a grain of sand inadvertently drop from a hovering scorer in rain from their umbrella into my action at Lang Lang and scrape a groove, on the right lug of a new action.

-

DenisA

- Posts: 1526

- Joined: Wed Nov 09, 2011 7:00 pm

- Location: Sunshine Coast, QLD

Re: 300 WSM & 7 SAUM rate of increased MV??

David thanks again for so much information. I've always believed that using bronze brushes makes more sense though there are a lot of people that advocate nylon brushes. I felt that I need to experience both before I could say with certainty that one is better than the other. 600 rounds in on the .284W and 300 rounds in on the 300WSM, I can already see using the bore scope that nylon doesn't clean carbon out as well as bronze (especially from the corners of the grooves). It does an OK job if combined with a couple of 30 minute boretech eliminator soaking periods, but certainly not as good. Nylon brushes do work well with copper fouling and so I can understand why some people who only base their cleaning regime on what the patch looks like afterwards might advocate nylon. The nylon does give a better indication of how much copper is left in the barrel as it doesn't give the false positives that a bronze brush does.

The interesting thing to see will be how well a nylon brush does the job once the throats start to get a little rough with fire cracking.

I really appreciate your description and pictures of refreshing the bore .

Is there a chance a setup like that could get jammed in a buttoned rifle that might have slight variations in twist rate at different points?

The interesting thing to see will be how well a nylon brush does the job once the throats start to get a little rough with fire cracking.

I really appreciate your description and pictures of refreshing the bore .

Is there a chance a setup like that could get jammed in a buttoned rifle that might have slight variations in twist rate at different points?

-

williada

- Posts: 969

- Joined: Wed Jul 22, 2009 12:37 am

Re: 300 WSM & 7 SAUM rate of increased MV??

Denis in the early days of making buttoned barrels with direct hydraulic control over the twist rate with a second hydraulic motor attached to a ram, the variations in pressures led to all sorts of twist rate variance down the tube. It was discovery learning and if you have never made a mistake you can't have done anything or you learned stuff all. The way Border Barrels do it over a mandrill, is superior but we were playing.

As far as variation in twist rate, a slight variation is ruinous to grouping except to say if it a gain twist where the progression is gradual and the leading edge of the lands have pressure maintained. Perce Pavey always used to say its all in the last six inches. The good gain twist barrels have that section at a constant twist and allows for the smith to play with length without altering the rate. With a gain twist its the last twist rate which determines bullet revolution. However they are bastards to lap because they jam. What the lappers of such barrels do is go down with a copper plug rather than a lead lap to clean a few feathers up on the top of the rifling which can occur and let the bullets do the lapping, and keeping them clean while they come to hand. There are too many things to go wrong with gain twist as the width of lands and grooves varies as well as the twist. Though I am not up to date with what they do now. Gain twist was traditionally achieved with cut barrels.

Good button barrels don’t require much lapping anyway after several reams following the drill a lap or hone then buttoning and tolerances determined by air gauges such as the Sheffield air gauge hold for the length of the barrel in the order of .0005” after just a final tickle with the lead lap.

If a barrel really needs remedial work, you have to be aggressive with grit on a lead lap and then follow up with a copper lap to dress the lands which get rounded by the lead lap.

The use of JB on a lead lap is really great for fouling and won’t damage the bore. Get a look at the lap I made for Tony and copy it Denis.

You can measure for variance in twist if you construct a device that is a long tube to insert up the barrel and allows a rod to pass through its internal. Both the end of the tube and the rod have provision to hold independent star gauges or tight patches. You can vary the trailing patch with your fingers. You mark both the tube and the rod at the rear. Just clarifying this bit with an edit. Because the rod and the tube turning points are a couple of inches apart, if the marks on the rod are not in the same clock face position then the twist rate is varying. Denis, I could keep you so busy you would not have time to shoot. David.

David.

As far as variation in twist rate, a slight variation is ruinous to grouping except to say if it a gain twist where the progression is gradual and the leading edge of the lands have pressure maintained. Perce Pavey always used to say its all in the last six inches. The good gain twist barrels have that section at a constant twist and allows for the smith to play with length without altering the rate. With a gain twist its the last twist rate which determines bullet revolution. However they are bastards to lap because they jam. What the lappers of such barrels do is go down with a copper plug rather than a lead lap to clean a few feathers up on the top of the rifling which can occur and let the bullets do the lapping, and keeping them clean while they come to hand. There are too many things to go wrong with gain twist as the width of lands and grooves varies as well as the twist. Though I am not up to date with what they do now. Gain twist was traditionally achieved with cut barrels.

Good button barrels don’t require much lapping anyway after several reams following the drill a lap or hone then buttoning and tolerances determined by air gauges such as the Sheffield air gauge hold for the length of the barrel in the order of .0005” after just a final tickle with the lead lap.

If a barrel really needs remedial work, you have to be aggressive with grit on a lead lap and then follow up with a copper lap to dress the lands which get rounded by the lead lap.

The use of JB on a lead lap is really great for fouling and won’t damage the bore. Get a look at the lap I made for Tony and copy it Denis.

You can measure for variance in twist if you construct a device that is a long tube to insert up the barrel and allows a rod to pass through its internal. Both the end of the tube and the rod have provision to hold independent star gauges or tight patches. You can vary the trailing patch with your fingers. You mark both the tube and the rod at the rear. Just clarifying this bit with an edit. Because the rod and the tube turning points are a couple of inches apart, if the marks on the rod are not in the same clock face position then the twist rate is varying. Denis, I could keep you so busy you would not have time to shoot.

Last edited by williada on Mon Apr 11, 2016 7:42 pm, edited 1 time in total.

-

DenisA

- Posts: 1526

- Joined: Wed Nov 09, 2011 7:00 pm

- Location: Sunshine Coast, QLD

Re: 300 WSM & 7 SAUM rate of increased MV??

williada wrote:

Denis, I could keep you so busy you would not have time to shoot.David.

Thanks David, but I think my wife has copyright on that phrase.

-

RDavies

- Posts: 2323

- Joined: Sun Feb 12, 2006 7:23 pm

- Location: Singleton NSW

Re: 300 WSM & 7 SAUM rate of increased MV??

I had an interesting day today cronographing my new 7mm barrel. It has around 80 shots through it including running in, some initial cronographing, then a ladder test followed by seating depth test.

Today I did a 3 way round robin primer test over the crony to see which one gave better spreads. The velocity in my initial crony test got it to around 2830 fps where I wanted it.

Today after 3 foulers, my first few shots were around 2830 fps again. After this, a few went up to 2880 fps. After 12 shots I cleaned it, thinking maybe it had fouled, causing a velocity jump.

After cleaning and 1 fouler, the velocity stayed at the 2870-2880 fps mark for the remaining 15 shots. It looks like it may have gotten over the hump at around 100 rounds, but I never suspected that the velocity jump would suddenly spike up over just a few rounds.

Today I did a 3 way round robin primer test over the crony to see which one gave better spreads. The velocity in my initial crony test got it to around 2830 fps where I wanted it.

Today after 3 foulers, my first few shots were around 2830 fps again. After this, a few went up to 2880 fps. After 12 shots I cleaned it, thinking maybe it had fouled, causing a velocity jump.

After cleaning and 1 fouler, the velocity stayed at the 2870-2880 fps mark for the remaining 15 shots. It looks like it may have gotten over the hump at around 100 rounds, but I never suspected that the velocity jump would suddenly spike up over just a few rounds.

-

Nathan P

- Posts: 98

- Joined: Tue Oct 15, 2013 11:03 am

Re: 300 WSM & 7 SAUM rate of increased MV??

I found similar results as Rod has described on Saturday while running in a new shehane barrel, at around the 40-50 round mark the mild load with 168s I was running jumped about 60 fps in one or two shots an stayed up around that area. I had to drop .6 of a grain to bring it back to where it was and it hasn't moved much till the 100 round mark

I plan to try and run another 50-100 round through the barrel before I start serious load development with 180s hopefully to avoid any more speed ups and give the brass a chance to harden up

I plan to try and run another 50-100 round through the barrel before I start serious load development with 180s hopefully to avoid any more speed ups and give the brass a chance to harden up

-

pjifl

- Posts: 883

- Joined: Fri Jun 17, 2005 12:15 pm

- Location: Innisfail, Far North QLD.

Re: 300 WSM & 7 SAUM rate of increased MV??

I saw an unexpected sudden increase in V with a new SAUM barrel at about 50 shots.

But I was experimenting with jump changing to slight jam and initially put it down to that at the time.

In retrospect, the barrel did seem to speed up apart from any other changes. Now at about 120 shots it seems quite stable.

Peter Smith.

But I was experimenting with jump changing to slight jam and initially put it down to that at the time.

In retrospect, the barrel did seem to speed up apart from any other changes. Now at about 120 shots it seems quite stable.

Peter Smith.

-

AlanF

- Posts: 7501

- Joined: Wed Jun 15, 2005 8:22 pm

- Location: Maffra, Vic

Re: 300 WSM & 7 SAUM rate of increased MV??

Peter,

Is there some sort of tipping point? Could it be that that barrels take a while to smooth out to a perfect pressure seal, and when the last impediment goes, it suddenly goes up in pressure, and velocity. Would be interesting to see pressure measurements over that initial period.

Alan

Is there some sort of tipping point? Could it be that that barrels take a while to smooth out to a perfect pressure seal, and when the last impediment goes, it suddenly goes up in pressure, and velocity. Would be interesting to see pressure measurements over that initial period.

Alan

-

DenisA

- Posts: 1526

- Joined: Wed Nov 09, 2011 7:00 pm

- Location: Sunshine Coast, QLD

Re: 300 WSM & 7 SAUM rate of increased MV??

I wasn't going to continue with this thread, but since its been brought up again I'll update my 300WSM saga... in case anyone's interested.

By 350 rounds I had to come down to 64.0gn from 64.5 for the same MV.

A couple of weeks ago I ran it through its paces in the Williada test. I was pretty shattered see that 64.0gn was now up to 2940 fps. The group with the best vert was 63.7gn but still too fast. I thought at the time that it was barrel heat from the testing process but realised soon after where the problem was.

When I loaded rounds for the Wiliada test, I had used a new batch of primers that I knew I'd be using for the Nationals. They were still Federal GM210m. Thinking about it all when I got home, I suspected the new primers may have caused the extra MV.

The following weekend at the club, I shot the first match with the old primers and 64.0gn for an average MV of 2915. I shot the second match with the new batch of primers and 63.7gn for an average MV of 2930fps...... for .3gn less powder.

This Sunday just gone I went and re-tested at 100y with the new primers to find my load again.

Long story short, with 500 rounds on this barrel I'm now at 63.3gn for the same MV that 67.1gn produced in the beginning.

This last MV increase is the biggest difference I have ever seen in a different batch number of the same primers. Approximately 20-25fps.

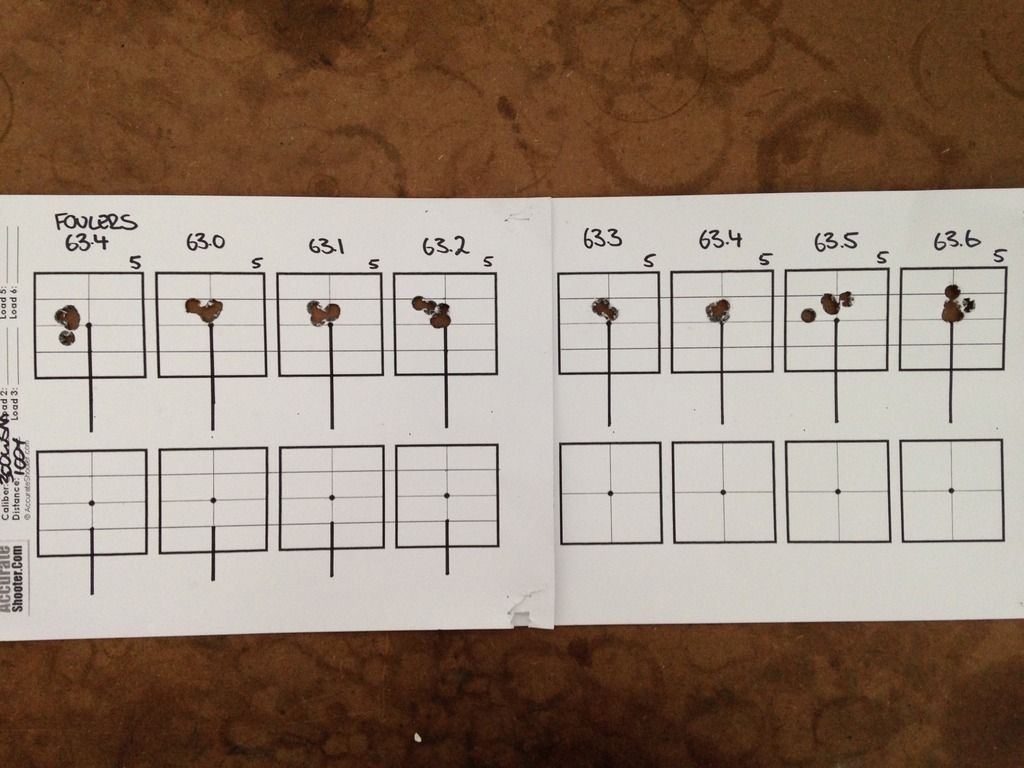

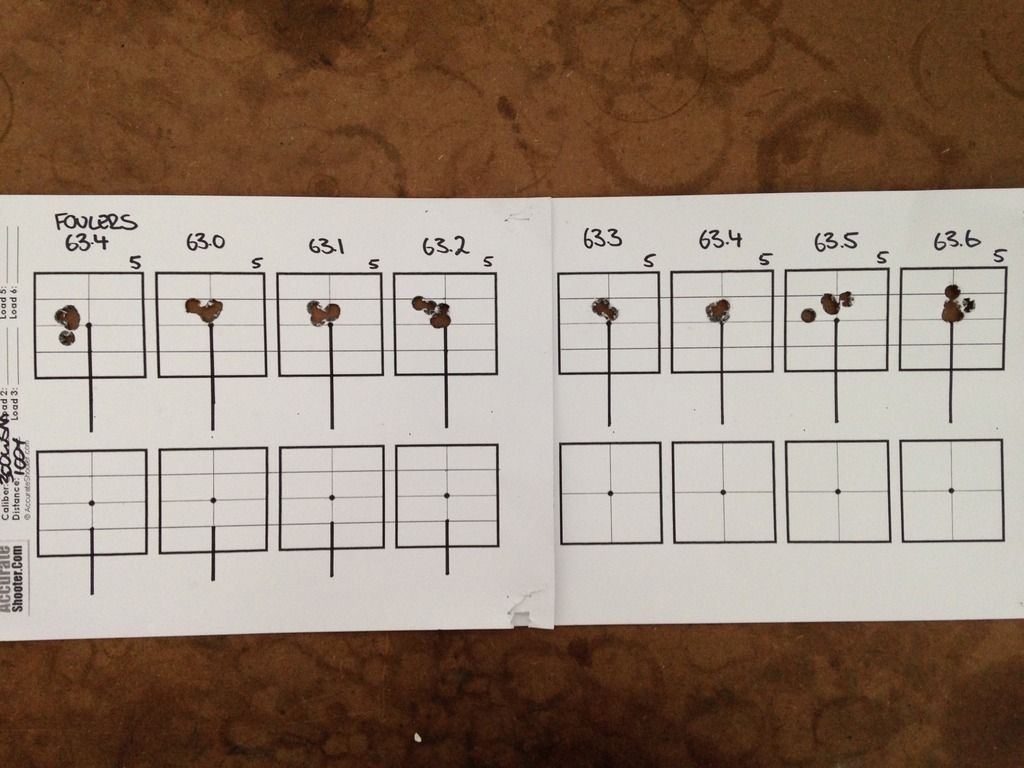

63.3gn averaged 2912fps. The low shot on the Foulers was the first cold clean bore. After that group I clicked .25 MOA right for the remainder of the test. The horizontal lines are .5" apart. I figure that generally give me about .2 - .25 moa vert across the node length.

I really hope this barrel is done speeding up. Its been an ordeal trying to tightly maintain a specific velocity so far.

Its been an ordeal trying to tightly maintain a specific velocity so far.

By 350 rounds I had to come down to 64.0gn from 64.5 for the same MV.

A couple of weeks ago I ran it through its paces in the Williada test. I was pretty shattered see that 64.0gn was now up to 2940 fps. The group with the best vert was 63.7gn but still too fast. I thought at the time that it was barrel heat from the testing process but realised soon after where the problem was.

When I loaded rounds for the Wiliada test, I had used a new batch of primers that I knew I'd be using for the Nationals. They were still Federal GM210m. Thinking about it all when I got home, I suspected the new primers may have caused the extra MV.

The following weekend at the club, I shot the first match with the old primers and 64.0gn for an average MV of 2915. I shot the second match with the new batch of primers and 63.7gn for an average MV of 2930fps...... for .3gn less powder.

This Sunday just gone I went and re-tested at 100y with the new primers to find my load again.

Long story short, with 500 rounds on this barrel I'm now at 63.3gn for the same MV that 67.1gn produced in the beginning.

This last MV increase is the biggest difference I have ever seen in a different batch number of the same primers. Approximately 20-25fps.

63.3gn averaged 2912fps. The low shot on the Foulers was the first cold clean bore. After that group I clicked .25 MOA right for the remainder of the test. The horizontal lines are .5" apart. I figure that generally give me about .2 - .25 moa vert across the node length.

I really hope this barrel is done speeding up.

Its been an ordeal trying to tightly maintain a specific velocity so far.

Its been an ordeal trying to tightly maintain a specific velocity so far.

-

williada

- Posts: 969

- Joined: Wed Jul 22, 2009 12:37 am

Re: 300 WSM & 7 SAUM rate of increased MV??

What Denis, have you been using lighter projectiles!!?  . Joking.

. Joking.  The primers do vary, and part of my routine is to establish the primer factor in the groups as I have mentioned before. So by revisiting that, you may have found the source of the issue.

The primers do vary, and part of my routine is to establish the primer factor in the groups as I have mentioned before. So by revisiting that, you may have found the source of the issue.

The other thing I note when doing the testing is the density altitude. Could be interesting? While the big boys group size remains fairly consistent with a small variation in velocity because of their mass and gyroscopic stability over a small test range, the velocity can vary a tad with the greater surface area exposed to the atmosphere. The other thing you can do is check that the angle of the boat-tail and its length are consistent with the larger calibres as this can effect the drag and velocity. Likewise a bigger surface area in the bore can take a little longer for the bullets to lap it clean if the barrel was not lead lapped thoroughly in the first instance. Putting your finger on that needs an inspection of the bore.

If its hitting the spot, don't worry because there are so many swings and roundabouts because your seating depth test should have sorted that out. David.

. Joking.

. Joking. The other thing I note when doing the testing is the density altitude. Could be interesting? While the big boys group size remains fairly consistent with a small variation in velocity because of their mass and gyroscopic stability over a small test range, the velocity can vary a tad with the greater surface area exposed to the atmosphere. The other thing you can do is check that the angle of the boat-tail and its length are consistent with the larger calibres as this can effect the drag and velocity. Likewise a bigger surface area in the bore can take a little longer for the bullets to lap it clean if the barrel was not lead lapped thoroughly in the first instance. Putting your finger on that needs an inspection of the bore.

If its hitting the spot, don't worry because there are so many swings and roundabouts because your seating depth test should have sorted that out. David.

-

DenisA

- Posts: 1526

- Joined: Wed Nov 09, 2011 7:00 pm

- Location: Sunshine Coast, QLD

Re: 300 WSM & 7 SAUM rate of increased MV??

[quote="williada"]What Denis, have you been using lighter projectiles!!?  . Joking.

. Joking.  quote]

quote]

LOL. Very funny David.

LOL. Very funny David.

Thanks.

. Joking.

. Joking. Thanks.

Return to “Equipment & Technical”

Who is online

Users browsing this forum: No registered users and 64 guests