the following are just some opinions and my experiences in these areas.

barrel blocks.

although, only an opinion, i support alan fraser's and brad y's thoughts on the possible choking of the barrel by clamped barrel blocks.

therefore to avoid this possibility, for all my barrel blocked rifles, efforts have been made to ensure that the barrels are fitted within the blocks in a stress free state.

ie whether using split or one piece blocks (in either steel or aluminium), all blocks were machined with around .002"-.003" clearance over barrel diameter.

barrels were then carefully glued/bedded in position with loctite 620.

regarding the theoretical stiffness/rigidity factors provided by barrel blocks, some may find the following of interest.

according to mr otteson, the following rigidity factors are provided for various actions.

rem 700 - 0.5 units

stolle panda - 3.9 units

rem 40xbr - 2.3 units

stolle polar (all steel approx 2"squarish shape) -28 units

sleeved rem 700 - 3.3 units.

as a comparison, (assuming correct calculations on my part)consider the following rigidity factors.

2 inch square steel block with 1.125" barrel - approx 40 units (used for Heavy Gun)

2 inch square aluminium block with 1.125" barrel - approx 15.4 units (used for 17lb Light Gun)

2 inch round aluminium block with 1.125" barrel - approx 9.7 units (used for 17lb Light Gun)

1.125" parrallel barrel - approx 2.4 units

2 inch wide X 3 inch deep timber section (working on approx youngs modulus being 1/18 of steel) - 9.06 units.

but, while theory is fine, it is important to test the rigidity of stocks.

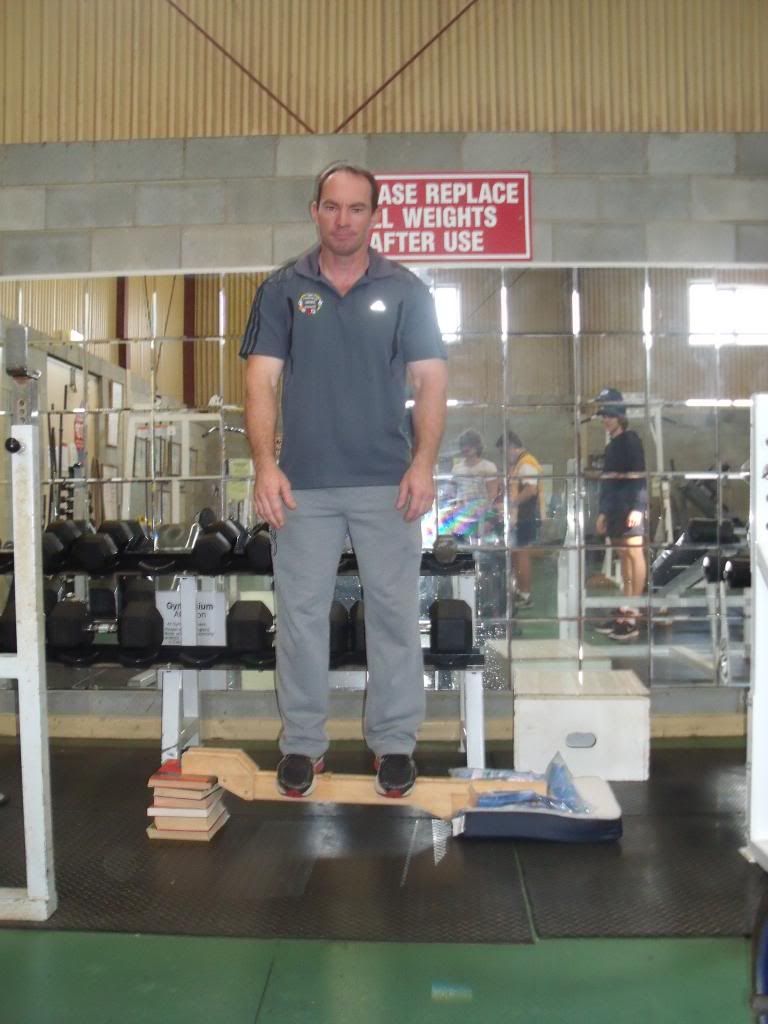

so with the assistance of students and staff at the narromine shooting institute.

a ninety kg load was applied to the plywood stock.

and then to really test the stock rigidity friendship around a 160 kg load was applied.

BTW -for this rifle the theoretical rigidity of the barrel block (including barrel) is similar to that of the stock at the mid section.

But as mentioned previously, unless the desired accuracy is achieved, it all means nothing.

cheers

dave g