Borescope evidence of the death of a very good barrel

Moderator: Mod

-

BATattack

- Posts: 1282

- Joined: Mon Dec 29, 2008 10:29 pm

I dunno mate. You've got an issue with that barrel. Up until now you've done everything rite and the barrel should be fine. If you put 200 rounds through it without cleaning they might be less likely to warrant your claim.

Filling in or building up the grooves may never happen. If they are soft areas and high pressure gas is leaking past the bullet during firing these areas will continue to erode due to gas gouging.

Filling in or building up the grooves may never happen. If they are soft areas and high pressure gas is leaking past the bullet during firing these areas will continue to erode due to gas gouging.

-

Frank Green

- Posts: 346

- Joined: Wed May 28, 2014 11:48 pm

Re: Borescope evidence of the death of a very good barrel

ecomeat wrote:My very good Bartlein barrel let me down big time at the NQRA Queens in Townsville a week ago.

After a discussion and inspection by Marty Lobert, Pete Smith, Mark Fairbairn, Alan Fraser and others, using Alans borescope at the conclusion of the event, i packed up and headed for home with my tail between my legs

.

I then took a number of photos and videos through my brighter, focussable borescope (much easier said than done, when you are by yourself !!).

I have since added Cameron McEwan, Dave McNamara, Matt Paroz, Craig McGowan and Paul Janzo to the list of "Consultants" asking for their opinions.

I thought some forum members might appreciate a few photos of my evidence:

This is a photo of a brand new, unfired 7mm Bartlein blank, with canted lands :

Note that the sloping (canted) sides of the land is very different to a more typical rifling. This is exactly what both of mine looked like when they were first chambered.

Here is a Maddco 7mm chambered in 284 Win that has had over 1400 shots fired through it

The sharp corner right on top is rounded off, but the lands are still in perfect condition.

This a second Maddco with just over 700 shots through it:

The sharp right angled corners are rounded off nicely, and it is a very low fouling barrel. It shot a 10 shot group of 8,25" at 1000 yards about 5 weeks ago.

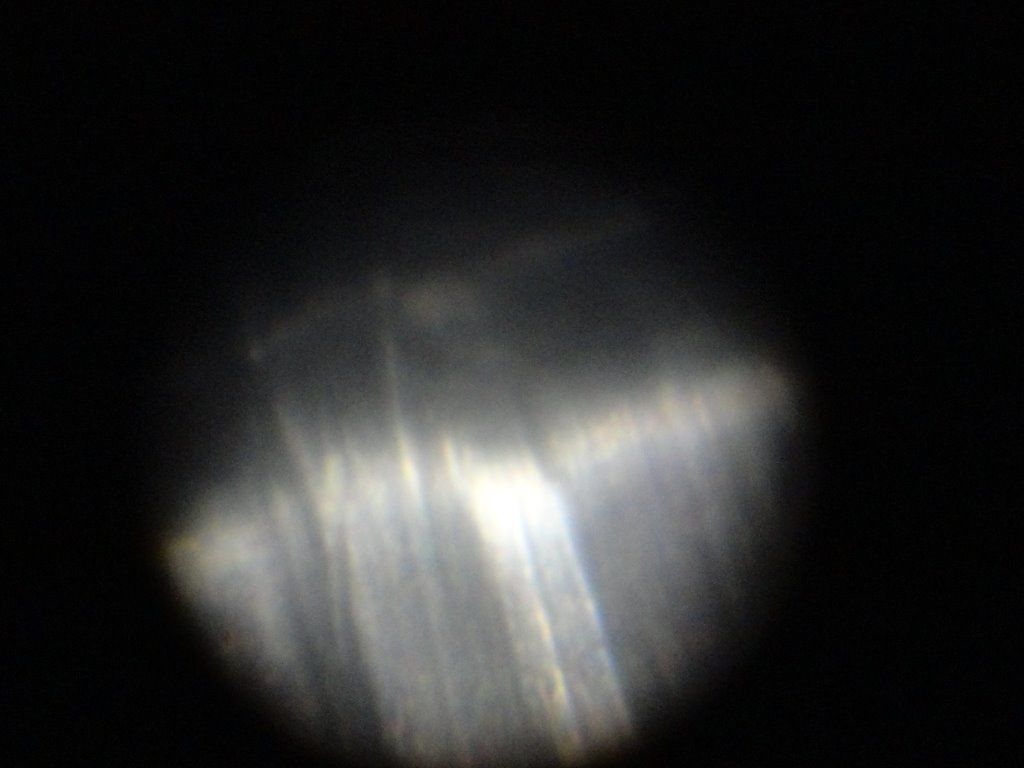

Hopefully you will understand my horror when i found that the top of the lands in my best barrel looked like this :

It is just like a jungle vine to look at through the 25 x power of the Hawkeye Borescope, and to get my camera to focus, i have to have the digital zoom right out to the maximum 10 x power, so remember that these images are effectively taken at 250 x power, or there abouts.

This what the muzzle of my problematical Bartlein looks like externally. You can see what looks like very clear, even tooling marks on the top of the lands

But inside, through my Hawkeye, the "evenly spaced look" just cant be seen.

It looks like this, with very uneven ridges and gouges. They run with the rifling twist, and the borecope has to move approx 1/4" forward for each ugly ridge/vine/gouge to cross from the Groove, up over the top of the land.....that should be/used to be flat...and down the other angled side to the next groove

In the photo above, you can see that the Groove is clean and completely unmarked, whereas the land looks like something out of a horror movie.

This is a short 24 sec video sequence, taken following a single Land for about 6", right in to the centre of the barrel. If you click on the still photo, it should open the Video, possibly in a seperate window

Its enough to make a grown man cry

This is another ugly shot showing a perfect, pristine Groove on the Left, and Land on the Right

Has anyone ever seen anything even vaguely resembling that ?? Non of my consultant experts ever have !! But there must be a lot of other shooters out there who have looked down barrels with a borescope.

It seems that i have three choices

A) Tomato stake

B)Try shooting 200-300 rounds without cleaning, in the hope that copper will fill in the ugly grooves, and eventually give each new projectile a relatively smooth path.

C) Try Moly coating barrel and bullets...again in the hope that the Moly or HBN would fill in the grooves, and smooth the path a bit

I have a second Bartlein that is also shooting very well at present, but at the 446 round mark, it is just starting to show faint signs through the borescope that it is headed down the same path as the first one.

In the following photo of one of the Lands, you can see the ugly "jungle vine" look just starting in two places. It is very faint, but it is definitely changing.

This second Bartlein put the first 3 shots (out of the 10 shot group that we shoot in Heavy Gun at 1000 yards Benchrest) into less than half an inch at 1000 yards about 3 weeks ago, so it is definitely still a "shooter". I dont want to discuss shot 4, that i put just on 14" away

Alan Fraser has got over 1000 rounds through the Bartlein that he got from me, and says its the best barrel he has ever had, bar none. He shot the highest Individual score with it on one day of the two day FCWC Teams event that our magnificent Aussie F Open Team won the Gold medal at Raton NM last year.

His doesnt look anything like mine !!

This is another photo of the second Bartlein, showing the first signs, I think. There are three seperate visible marks

This is a 22 sec video of the Maddco barrel with 1400 rounds fired, following a single Land for about 3" Dont forget that you need to click on the "still" to open all of the following short videos.

This is a short video of the second Maddco, with some 712 shots fired. Its not really much different to the first Maddco with twice as many shots

This is a 27 sec video of the second Maddco, with 712 shots, but this time staying in the same spot and just rotating the mirror

So this new Bartlein blank is what mine should look like when rotating the borescope:

But unfortunately, my "best" one looks like this, with 804 shots

And its little brother looks like its headed down the same path. This is the 446 round "Bartlein 2" when rotating the borescope

Hopefully some forum members might have found some information of interest in there amongst my pain.

I think I need a hug !](./images/smilies/eusa_wall.gif)

](./images/smilies/eusa_wall.gif)

Hello Anthony and everyone here on this forum! I'm on other forums and never knew about this one and I guess cannot be every where at the same time.

Where to start? Not sure so please bare with me! Have not read the entire thread as it's on 4 pages now but have read your emails that you sent and the start of this thread.

Never seen anything like this before! If it was a tooling problem and the tool dragging or the head dragging etc....it most likely would've taking chunks out of the sides of the lands which I don't see any sign of. Also if it was having a major problem during rifling it should've trashed the tooling completely wrecked/jammed the rifling head in the bore of the barrel etc...

Also all of the barrels get inspected visually and if anything causes concerns we bore scope them as well. I'm not saying something cannot get thru/past us as we are human but to have two barrels like this the odds start working against this happening.

My first question is with the very first picture. If that is a new Bartlein is the same barrel that after shooting it has the marks on tops of the lands? If so I'm going to say the damage occured sometime after the barrel was installed. If the marks were not there prior to installation and shooting something like this won't/shouldn't just suddenly appear after shooting some rounds down it.

Myself and Jeff here...both of our F-Class open guns are set up in .284win. Jeff's barrel has approx. 1000 rounds on it now and still shoots just fine and nothing out of the ordinary. My gun only has approx. 400 rounds on it. The last I shot my rifle was two summers ago. I shot it in only one mid range F-class match locally and won the match and set range record with the gun that still stands. Again no issues.

I'd like to know the serial numbers of the barrels if you have them or the approximate date you purchased them and from who as that would help me for looking back at records etc...Guys the s/n's mean everything to us. It tells me what lot of steel the barrels came out of, all the details to what the barrel was made to and I can even tell you who rifled the barrel here etc....whenever there is a problem with a barrel and we can get the s/n information I'll look back thru the records and I try to see if there is a pattern to anything going on. So when you have your gunsmith install a barrel (regardless of the barrel maker) have this information recorded for your own records. Chances are it will never mean anything but if you ever have a problem with anything it's good information to have.

The only time I've ever seen anything close to this (drag marks/scratches on tops of the lands primarily) is from cleaning damage. I've seen this happen primarily with guys using the paste type cleaners and using them heavily. It will leave drag marks/scratches that run the length of the bore and and usually the tops of the lands take the most damage. Also I feel when shooters use the paste type cleaners I don't feel they get it completely cleaned out. Then the next rounds fired down the barrel the bullets will drag the paste particles down the bore and under pressure will scratch/gouge the bore. I also feel using the paste type cleaners can lead to copper fouling issues as well. Basically your lapping the barrel every time you use them.

From what I've read here and in your email's you didn't use any type of paste cleaners but I wanted to bring it up as it's the only time I've seen damage similar to this and I feel this has been the cause.

I don't feel it has anything do do with the hardness of the steel right off hand. You would think if that was the case the grooves of the rifling should be gouged/scratched up really bad as well but from the pictures and what I can see here that doesn't necessarily seem to be the case.

I would like you to cut approx. 3" off of one of the barrels and send it to us so we can physically look at it cut it apart etc....

We stand behind everything we make and do. If it is something that we caused we will replace the barrel/s'.

Shooting it to try and fill the voids/scratches etc...I feel is going to be a waste of time. So I would save your ammo/bullets/time/money in trying to do this.

Will help in any way we can. If you could get me some more information it would be appreciated.

Best Regards,

Frank

Bartlein Barrels

-

DaveMc

- Posts: 1453

- Joined: Mon Aug 22, 2011 6:33 pm

Thank you Frank for taking the time to reply on the forum here. No one on this thread has seen this problem before either and the biggest reason I suggested getting in contact with you directly before investigating much further was to see if you guys had seen anything like it. No doubt you would see more barrels and barrel issues than most of us and in particular if there was ever any manufacturing glitches particular to your methods/materials that may slip through the net. The fact that you have never seen anything like it as well (as I suspected) says a lot. So far the only two barrels like this are in Tony's possession.

The issue he (and others) have trouble understanding ("understandably") is why it isn't happening to his Maddcos!????

I have some possible explanations for this and will approach them later but firstly (if we still have your attention) I would like to summarize some suggestions so far to save you reading back through all and would be great to get your opinion (especially on those that particularly relate to manufacturing) so I will start there.

Please Note; We noticed the gouges were approx in direction of barrel bore rather than parallel with rifling - so what processes would leave gouges (scratches, or cracking even) parallel with bore and not with rifling?

Some suggestions so far (please note these are not mine and I doubt any manufacturing issues but previous plausible or semi-plausible suggestions from the thread are included - I apologise if I missed some) starting with possible manufacturing issues that you may wish to comment on...???

1) Drill or reamer chatter during the initial boring process before rifling is cut (such that bottom of grooves are still clean). This could possibly explain marks parallel with barrel (not rifling) but these seem to get worse with shooting and don't look like chatter marks - more like gouges. I cannot see this being and issue and it would have been a dog from the start.

2) "gouging" of the lapping rod done during the initial lapping -before rifling - (not sure if you use a machine lap or hand lap and whether the barrel is spun during this process??). - once again should be noticed early and not getting worse with time. This barrel shot very well initially as above so doubt it.

3) Soft parent material or heat treatment. (I agree with you here I think we would see rounding of the lands and scratches running parrallel with rifling and in bottom of grooves)

Some other suggestions:

4) Foreign material in powder such as stainless steel tumbling media or small ball bearings (used in lubricating necks) or similar (even sand getting into shells sitting on loading bench whilst filling sand bags??) that were blasted down barrel (perhaps just in one or two batches of shells such that only got fired in Bartleins and not Maddcos. This would explain the passage over lands parallel to bore.

5) Cleaning rod end ferrule gouging after brush etc removed and on way back through bore (as would not be spinning with rifling and would not gouge bottom of grooves

6) "Torque" of projectile through rifling causing lands movement

7) Abrasive cleaning compounds or other cleaning process. In this case i can't see it. If it was parallel to rifling then yes but not this time. Brush, patches and pastes would all be running parallel with rifling even if left in bore and under "fire lapping" scenario.

Very strange and obviously very rare case that we are all intrigued with

Thanks for your contribution

Dave McNamara

The issue he (and others) have trouble understanding ("understandably") is why it isn't happening to his Maddcos!????

I have some possible explanations for this and will approach them later but firstly (if we still have your attention) I would like to summarize some suggestions so far to save you reading back through all and would be great to get your opinion (especially on those that particularly relate to manufacturing) so I will start there.

Please Note; We noticed the gouges were approx in direction of barrel bore rather than parallel with rifling - so what processes would leave gouges (scratches, or cracking even) parallel with bore and not with rifling?

Some suggestions so far (please note these are not mine and I doubt any manufacturing issues but previous plausible or semi-plausible suggestions from the thread are included - I apologise if I missed some) starting with possible manufacturing issues that you may wish to comment on...???

1) Drill or reamer chatter during the initial boring process before rifling is cut (such that bottom of grooves are still clean). This could possibly explain marks parallel with barrel (not rifling) but these seem to get worse with shooting and don't look like chatter marks - more like gouges. I cannot see this being and issue and it would have been a dog from the start.

2) "gouging" of the lapping rod done during the initial lapping -before rifling - (not sure if you use a machine lap or hand lap and whether the barrel is spun during this process??). - once again should be noticed early and not getting worse with time. This barrel shot very well initially as above so doubt it.

3) Soft parent material or heat treatment. (I agree with you here I think we would see rounding of the lands and scratches running parrallel with rifling and in bottom of grooves)

Some other suggestions:

4) Foreign material in powder such as stainless steel tumbling media or small ball bearings (used in lubricating necks) or similar (even sand getting into shells sitting on loading bench whilst filling sand bags??) that were blasted down barrel (perhaps just in one or two batches of shells such that only got fired in Bartleins and not Maddcos. This would explain the passage over lands parallel to bore.

5) Cleaning rod end ferrule gouging after brush etc removed and on way back through bore (as would not be spinning with rifling and would not gouge bottom of grooves

6) "Torque" of projectile through rifling causing lands movement

7) Abrasive cleaning compounds or other cleaning process. In this case i can't see it. If it was parallel to rifling then yes but not this time. Brush, patches and pastes would all be running parallel with rifling even if left in bore and under "fire lapping" scenario.

Very strange and obviously very rare case that we are all intrigued with

Thanks for your contribution

Dave McNamara

Last edited by DaveMc on Thu May 29, 2014 10:54 am, edited 2 times in total.

-

KHGS

- Posts: 934

- Joined: Thu Oct 20, 2005 12:46 am

- Location: Cowra NSW

I have always make a point of lightly stamping the serial number of all barrels that come with a S/N on the underside of the reinforce when I fit such barrels.

As Mr Green states this number is critical to tracking down POSSIBLE steel & manufacturing faults. I will also state here & now that despite some lines of thinking, faulty barrels are rare in this day & age. Premium barrel makers have perfected the art pretty damn well.

A barrel that is easy to machine does not necessarily mean that it is softer than it should be either. What I see from the pics do not translate to me that the steel or manufacturing process it to blame. I stand by my previous post & firmly believe (for what it is worth) that it is due to the inadvertent introduction of some kind of foreign object or material.

Keith H

As Mr Green states this number is critical to tracking down POSSIBLE steel & manufacturing faults. I will also state here & now that despite some lines of thinking, faulty barrels are rare in this day & age. Premium barrel makers have perfected the art pretty damn well.

A barrel that is easy to machine does not necessarily mean that it is softer than it should be either. What I see from the pics do not translate to me that the steel or manufacturing process it to blame. I stand by my previous post & firmly believe (for what it is worth) that it is due to the inadvertent introduction of some kind of foreign object or material.

Keith H

-

ecomeat

- Posts: 1137

- Joined: Tue Jun 01, 2010 11:07 pm

- Location: Pimpama QLD

As you would realise, Frank Green and i had had emails backwards and forwards. I am thrilled to report that they have offered me a replacement barrel at no charge, and in return, i am going to cut 3" off the end of the barrel and get it to them asap in an airfreight satchell.

Great to see a big name barrel maker looking after a foreign customer

I/we will advise what they find once they get the bit of barrel and get the testing results.

Thanks Frank ! You are a Champion.

Tony

Great to see a big name barrel maker looking after a foreign customer

I/we will advise what they find once they get the bit of barrel and get the testing results.

Thanks Frank ! You are a Champion.

Tony

Extreme accuracy and precision shooting at long range can be a very addictive pastime.

-

Frank Green

- Posts: 346

- Joined: Wed May 28, 2014 11:48 pm

DaveMc wrote:Thank you Frank for taking the time to reply on the forum here. No one on this thread has seen this problem before either and the biggest reason I suggested getting in contact with you directly before investigating much further was to see if you guys had seen anything like it. No doubt you would see more barrels and barrel issues than most of us and in particular if there was ever any manufacturing glitches particular to your methods/materials that may slip through the net. The fact that you have never seen anything like it as well (as I suspected) says a lot. So far the only two barrels like this are in Tony's possession. This is one thing that doesn't make any sense. If several people got barrels at the same time and lets assume they came out of the same batch/run we made then more than one person should be having the problem. They would've all been made with the same tooling and for the most part out of the same lot of steel.

The issue he (and others) have trouble understanding ("understandably") is why it isn't happening to his Maddcos!???? I don't know either. One question I have is, " Were the barrels bore scoped before putting them on the gun and or before being shot? If they were and these marks were not in the barrels before being shot or being cleaned then something happened during shooting/cleaning. Was anything done different between the Maddco's and ours? The damage that is visible in those barrels seems to be to the point you can see it with the naked eye. As the one picture looking from the muzzle end was not taken with a bore scope. If it's that visible I would like to stand on a stack of bibles and say no way did they leave here looking like that but I will say we are all human and anything is possible but I feel the odds are against it.

I have some possible explanations for this and will approach them later but firstly (if we still have your attention) I would like to summarize some suggestions so far to save you reading back through all and would be great to get your opinion (especially on those that particularly relate to manufacturing) so I will start there.

Please Note; We noticed the gouges were approx in direction of barrel bore rather than parallel with rifling - so what processes would leave gouges (scratches, or cracking even) parallel with bore and not with rifling?

Some suggestions so far (please note these are not mine and I doubt any manufacturing issues but previous plausible or semi-plausible suggestions from the thread are included - I apologise if I missed some) starting with possible manufacturing issues that you may wish to comment on...???

1) Drill or reamer chatter during the initial boring process before rifling is cut (such that bottom of grooves are still clean). This could possibly explain marks parallel with barrel (not rifling) but these seem to get worse with shooting and don't look like chatter marks - more like gouges. I cannot see this being and issue and it would have been a dog from the start. It wouldn't be from drilling. The drill size is approx. .007"-.008" under bore size. The bore reamer will take the size to only about .0002" under bore size. So any drill marks will get taken out during the bore reaming process. If the marks were from bore reaming they would be rings and not drag marks running the length of the barrel. After bore reaming the barrels get prelapped before rifling. If there were abnormal marks or something wrong with the bore before rifling the guys should feel it during prelapping for one and the barrels get visually inspected after reaming and after prelapping. Both with the naked eye, using eye loupes and using the bore scope. So I'm going to say it's not with either of these processes.

2) "gouging" of the lapping rod done during the initial lapping -before rifling - (not sure if you use a machine lap or hand lap and whether the barrel is spun during this process??). - once again should be noticed early and not getting worse with time. This barrel shot very well initially as above so doubt it. Again the barrels get visually inspected as well with the bore gauges for size before rifling. The barrel is spun during prelapping but I've never seen any type of marks like that caused from prelapping. Going back to your comment it seems like the barrel got worse as it was shot. If that's the case then something else is going on but the big question is what is going on?

3) Soft parent material or heat treatment. (I agree with you here I think we would see rounding of the lands and scratches running parrallel with rifling and in bottom of grooves) I'm going to say no for the most part that the steel is soft or improper heat treatment. Can it be possible that a section of the steel bar wasn't properly heat treated etc...sure anything is possible but I would say if these barrels came out of a batch of steel that was from 40,000 pounds of steel then more than just a couple of barrels should've been effected from a improper heat treatment process. We should have more calls/complaints/problems etc...but don't have any.

Some other suggestions:

4) Foreign material in powder such as stainless steel tumbling media or small ball bearings (used in lubricating necks) or similar (even sand getting into shells sitting on loading bench whilst filling sand bags??) that were blasted down barrel (perhaps just in one or two batches of shells such that only got fired in Bartleins and not Maddcos. This would explain the passage over lands parallel to bore. This is my first guess. Something was shot down/thru the barrel (foreign material etc..) or some type of cleaning media weather on the brass or bullets or used to clean the barrel was in the barrel or left on the ammo and when fired it got pushed down the barrel. That would easily explain the marks and usually the lands take more of a beating then the grooves do believe it or not or should I say it shows up easier on the lands. I've seen it before where shooters have left an abrasive cleaner in the bore and didn't get it all out and the tops of the lands took the worse of it but the grooves looked almost untouched.

5) Cleaning rod end ferrule gouging after brush etc removed and on way back through bore (as would not be spinning with rifling and would not gouge bottom of grooves? Again I say yes and the lands take the beating more than anything else. The lands stick up in the bore as we all know. So any cleaning rod drag etc...it's going to go over/ride on the lands etc....

6) "Torque" of projectile through rifling causing lands movement? I'm going to say no the lands won't move/distort per say. Having a grit or compound/an abrasive on the bullets or in the bore of the barrel the bullet basically being a press fit is going to grind/smear the abrasive down the bore and is under pressure as well. The grit/abrasive has no where to go but get forced between the bore of the barrel and the bullet.

7) Abrasive cleaning compounds or other cleaning process. In this case i can't see it. If it was parallel to rifling then yes but not this time. Brush, patches and pastes would all be running parallel with rifling even if left in bore and under "fire lapping" scenario. I don't necessarily agree. From what I've seen the drag marks/scratches will run the length wise of the barrel but won't always be consistent. They can be in different spots etc...

Very strange and obviously very rare case that we are all intrigued with

Thanks for your contribution

Dave McNamara

Dave, Thanks for the kind words! I will try and answer your questions and thoughts the best I can.

Later, Frank

Last edited by Frank Green on Thu May 29, 2014 11:29 pm, edited 1 time in total.

-

Frank Green

- Posts: 346

- Joined: Wed May 28, 2014 11:48 pm

Dave, To touch on your questions some more that we didn't talk about would be..... Could the marks be caused from the rifling process and or the finish lapping process after the barrel has been rifled?

I'm going to say no off hand to the first part of that question. The rifling process. We do single point cut rifling. If a chip lets say was hung up on the cutter or if the steel wasn't cutting properly or something was wrong with the tool one of two things would happen.

1.) The cutter should be taking chunks out of the sides of the lands or in the grooves. This is what we call skidders. Not what appears to be drag marks.

2.) When something like this is happening usually it will trash the tooling which will include the rifling head and we also loose the barrel.

3.) If there was a build of material on the rifling head which we have seen any abnormal marks are confined to the tops of the lands and doesn't effect the sides of the lands.

Later, Frank

I'm going to say no off hand to the first part of that question. The rifling process. We do single point cut rifling. If a chip lets say was hung up on the cutter or if the steel wasn't cutting properly or something was wrong with the tool one of two things would happen.

1.) The cutter should be taking chunks out of the sides of the lands or in the grooves. This is what we call skidders. Not what appears to be drag marks.

2.) When something like this is happening usually it will trash the tooling which will include the rifling head and we also loose the barrel.

3.) If there was a build of material on the rifling head which we have seen any abnormal marks are confined to the tops of the lands and doesn't effect the sides of the lands.

Later, Frank

-

Frank Green

- Posts: 346

- Joined: Wed May 28, 2014 11:48 pm

KHGS wrote:I have always make a point of lightly stamping the serial number of all barrels that come with a S/N on the underside of the reinforce when I fit such barrels.

As Mr Green states this number is critical to tracking down POSSIBLE steel & manufacturing faults. I will also state here & now that despite some lines of thinking, faulty barrels are rare in this day & age. Premium barrel makers have perfected the art pretty damn well.

A barrel that is easy to machine does not necessarily mean that it is softer than it should be either. What I see from the pics do not translate to me that the steel or manufacturing process it to blame. I stand by my previous post & firmly believe (for what it is worth) that it is due to the inadvertent introduction of some kind of foreign object or material.

Keith H

Keith, Most gunsmiths don't restamp the s/n on the barrel like you do and I applaud it. Some gunsmiths will take a real thin cut off the breech face (you end up with something that looks like a coin) and they give this to the customer. Then the customer has all the information that was stamped on the breech face of the barrel and it was saved. Some gunsmiths when they give they're customer an invoice will record the s/n on the invoice when they do the installation work.

This is also why when we ship a barrel to the customer the s/n is also entered on the invoice.

The s/n means everything to us and sad to say some barrel makers don't s/n they're barrels. The s/n to us I can tell you what lot of steel it came out of, caliber, number of grooves, type of steel etc...and I can even tell who in the shop rifled the barrel and if I have a question on something I can go back to the rifler/worker as well and talk with him.

Your other comments about the steel and machineability etc...I agree with.

Later, Frank

-

Frank Green

- Posts: 346

- Joined: Wed May 28, 2014 11:48 pm

ecomeat wrote:As you would realise, Frank Green and i had had emails backwards and forwards. I am thrilled to report that they have offered me a replacement barrel at no charge, and in return, i am going to cut 3" off the end of the barrel and get it to them asap in an airfreight satchell.

Great to see a big name barrel maker looking after a foreign customer

I/we will advise what they find once they get the bit of barrel and get the testing results.

Thanks Frank ! You are a Champion.

Tony

No not a champion! Just do what I can and help out the best I can. Get me that cut off piece. Email me the specs. of the barrel you purchased so I can get one going for you. When you get a chance answer my questions I emailed you the best you can please.

Later, Frank

-

Frank Green

- Posts: 346

- Joined: Wed May 28, 2014 11:48 pm

I'd like to share a thread that I found on Benchrest Central last week.

http://benchrest.com/showthread.php?894 ... nity/page2

My post is about half way down on the second page.

We've run into this problem before and never thought it would be asked on a public forum and that more than one person had thought about doing it. Guess I was wrong.

A few years ago a top benchrest shooter here in the States called his gunsmith and complained to him that we had bad steel. The gunsmith called me about it. The shooters complaint was that our barrels were pushing steel (in the throat area of the chamber/bore). I asked the gunsmith to explain to me what that meant. He said he wasn't sure but that's what he was being told. I asked the gunsmith did he have one of the barrels in hand or looked at them or could send me one to look at. He said no but the shooter was complaining it was happening with 2 barrels. Then the gunsmith was being blamed for using a dull chamber reamer.

Customer/shooter never called us about the problem.

The gunsmith goes to a benchrest match a few weeks later. The shooter/customer was there shooting as well. The gunsmith went over to talk to him and look at the barrels. The gunsmith caught the shooter wrecking a 3rd barrel. The smith called me right away and said we were both off the hook!

He caught the shooter using a cordless drill with a wooden shaft chucked up in it and the drill set on high speed (approx. 3000rpm) and had steel wool or emery cloth/sand paper on the end of the shaft. The shooter was concerned about the carbon ring build up in the throat and was attempting to get the carbon ring out of the chamber but he was pushing the abrasive material up into the bore of the barrel and was gouging/tearing the metal all up.

I had to share this with all of you.

Later, Frank

http://benchrest.com/showthread.php?894 ... nity/page2

My post is about half way down on the second page.

We've run into this problem before and never thought it would be asked on a public forum and that more than one person had thought about doing it. Guess I was wrong.

A few years ago a top benchrest shooter here in the States called his gunsmith and complained to him that we had bad steel. The gunsmith called me about it. The shooters complaint was that our barrels were pushing steel (in the throat area of the chamber/bore). I asked the gunsmith to explain to me what that meant. He said he wasn't sure but that's what he was being told. I asked the gunsmith did he have one of the barrels in hand or looked at them or could send me one to look at. He said no but the shooter was complaining it was happening with 2 barrels. Then the gunsmith was being blamed for using a dull chamber reamer.

Customer/shooter never called us about the problem.

The gunsmith goes to a benchrest match a few weeks later. The shooter/customer was there shooting as well. The gunsmith went over to talk to him and look at the barrels. The gunsmith caught the shooter wrecking a 3rd barrel. The smith called me right away and said we were both off the hook!

He caught the shooter using a cordless drill with a wooden shaft chucked up in it and the drill set on high speed (approx. 3000rpm) and had steel wool or emery cloth/sand paper on the end of the shaft. The shooter was concerned about the carbon ring build up in the throat and was attempting to get the carbon ring out of the chamber but he was pushing the abrasive material up into the bore of the barrel and was gouging/tearing the metal all up.

I had to share this with all of you.

Later, Frank

-

AlanF

- Posts: 7501

- Joined: Wed Jun 15, 2005 8:22 pm

- Location: Maffra, Vic

Thanks to Frank and Bartlein for replacing the barrel. This sort of attitude to customer satisfaction is to be applauded!

Now the next question for you Frank is, what can be done to improve the availability of Bartleins in Australia? I realise that all the big US barrel makers are struggling to meet demand at the moment, but Bartleins have been like hen's teeth in Australia for years. Other US brands like Broughton, Pacnor, Lilja, and particularly Krieger have been obtainable, why not Bartlein?

Alan

Now the next question for you Frank is, what can be done to improve the availability of Bartleins in Australia? I realise that all the big US barrel makers are struggling to meet demand at the moment, but Bartleins have been like hen's teeth in Australia for years. Other US brands like Broughton, Pacnor, Lilja, and particularly Krieger have been obtainable, why not Bartlein?

Alan

-

Frank Green

- Posts: 346

- Joined: Wed May 28, 2014 11:48 pm

AlanF wrote:Thanks to Frank and Bartlein for replacing the barrel. This sort of attitude to customer satisfaction is to be applauded!

Now the next question for you Frank is, what can be done to improve the availability of Bartleins in Australia? I realise that all the big US barrel makers are struggling to meet demand at the moment, but Bartleins have been like hen's teeth in Australia for years. Other US brands like Broughton, Pacnor, Lilja, and particularly Krieger have been obtainable, why not Bartlein?

Alan

Alan, There are a couple of other guys working on getting export approval/import permits etc...at this time. The only one that I know of that had a valid permit was David Kerr.

Who all has a permit to import on your end I don't know. So that's where it's got to start. I know the permits are a pain but we don't have a way around it.

If you could get together with some other guys and get some sort of an agreement amongst yourselves or with a gunsmith etc...work together on ordering the barrels, shipping, permits etc...what or who is buying from the other barrel makers etc...I cannot comment on as I don't know.

Later, Frank

-

Frank Green

- Posts: 346

- Joined: Wed May 28, 2014 11:48 pm

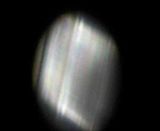

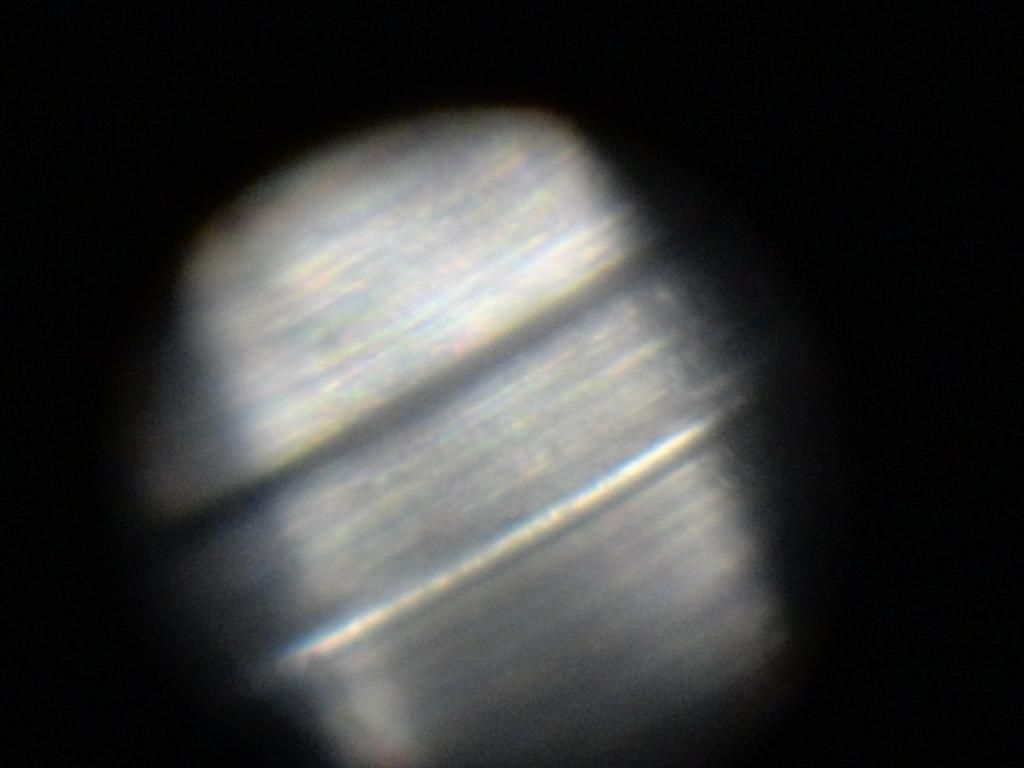

Here are some pictures of a couple of different barrels. Sorry if some are blurry.....

First group of pictures are of a F-TR barrel in .308win. Shot with 185gr. Berger's. Barrel has a little under 3000 rounds on it. All normal looking nothing out of the ordinary etc...this is one of my customers barrels that he pulled off as the accuracy had dropped to 1/2moa and is not good enough for him anymore. I've shot on team matches with him and against him! LOL! Great shooter!

Pictures start at the chambers/case mouth area and go up the throat to approx. 4" into the bore of the barrel.

Next pictures are of Jeff's barrel here. It's on his F-Class gun and is in .284win. and has 1000 rounds on it. Needs to be cleaned and it has some carbon build up but shoots like a million bucks.

again nothing out of the ordinary. Has normal wear and doesn't copper foul etc...

Later, Frank

First group of pictures are of a F-TR barrel in .308win. Shot with 185gr. Berger's. Barrel has a little under 3000 rounds on it. All normal looking nothing out of the ordinary etc...this is one of my customers barrels that he pulled off as the accuracy had dropped to 1/2moa and is not good enough for him anymore. I've shot on team matches with him and against him! LOL! Great shooter!

Pictures start at the chambers/case mouth area and go up the throat to approx. 4" into the bore of the barrel.

Next pictures are of Jeff's barrel here. It's on his F-Class gun and is in .284win. and has 1000 rounds on it. Needs to be cleaned and it has some carbon build up but shoots like a million bucks.

again nothing out of the ordinary. Has normal wear and doesn't copper foul etc...

Later, Frank

-

DaveMc

- Posts: 1453

- Joined: Mon Aug 22, 2011 6:33 pm

I would also like to thank you Frank for taking a huge amount of time to address this and give us some manufacturers input here. This along with the extremely generous replacement says a lot about your attitude to customer service. You have probably gained quite a few fans.

One of the things that sticks in my mind from our recent trip to the states was the popularity of Bartlein Barrels amongst the top US shooters at the world championships.

One of the things that sticks in my mind from our recent trip to the states was the popularity of Bartlein Barrels amongst the top US shooters at the world championships.

Last edited by DaveMc on Fri May 30, 2014 10:13 am, edited 1 time in total.

Return to “Equipment & Technical”

Who is online

Users browsing this forum: No registered users and 120 guests